Planar G-Code to multi-axis robotized printing

This project consisted at integrating G-Code, generated by FDM slicer softwares

(such as Ultimaker Cura), for robotic offline programming (path-planning).

It enables large format printing using standard six-axis robots.

Technical challenges are mainly related on how to solve inverse kinematics without wrist singularities,

collision-free, and with near-constant printing speed.

Check out

Digital Twin Manufacturing Process simulation

Automated Manufacturing processes consist at building parts using a machine, by material removal or addition.

In this project, I used and customized software tools for simulating such manufacturing processes.

Those tools integrates a virtual controller (Siemens CNC), allowing to use a digital twin of the real machine, in order

to get the true kinematics motions and cycle-times, for accurate offline simulation.

The core software technology integrates powerful collision detection algorithms and material deposition simulation features.

Check out

Visual Scripting for CAD/CAM

In this project, I implemented a visual scripting engine for robot control and geometry modeling (Open-Cascade kernel).

The goal is to have a no-code approach, for parametric CAD modeling and kinematics path-planning.

If you want to automate and improve ergonomy of some of your CAD/CAM processes or in-house software tools, it's possible.

Check out

CATIA V5 Automation

In this project, I used the CATIA V5 Visual Basic Scripting capabilities for automating repetitive tasks.

For example, building drawing sheets from 3D part models, converting drafts to solids, analyzing models,

meshing for Part Analysis (FEA).

Check out

Physics-based algorithm development

The fiber placement manufacturing process consists at depositing composites tape material on a mold, with consolidation ensured by an elastic roller.

In this project, a numerical analysis tool was developed for simulating the deformation of the compacting roller under loading.

The idea was to get a compromise between accuracy, computation time, and price (so without using commercial CAE and FE-solver tools).

An algorithm was developed (C++), and results were compared with the Simulia Abaqus Standard solver.

Check out

Filament Winding process tool

Filament winding is an additive manufacturing process for quickly building tubes or pressure vessels

by winding composites materials on a rotating mandrel.

In this project, the numerical analysis of filament winding paths (semi-geodesics) was implemented.

The pre-processing and results display was done through a form made in JavaScript, available from cloud.

Check out

Laser-Assisted Tape Placement

The additive manufacturing processes such as Tape placement and Filament Winding, consist at heating the thermoplastics composites material using a laser device.

The heating phase plays a crucial role for layup quality, since temperature needs to reach a minimum (bonding) but not exceed a limit (material degradation).

That's why numerical simulation can help predict the temperature peak at nip-point, and also optimize the process conditions (layup speed, heating power,..).

A dedicated algorithm was developed, to implement both optical and heat transfer numerical models.

Check out

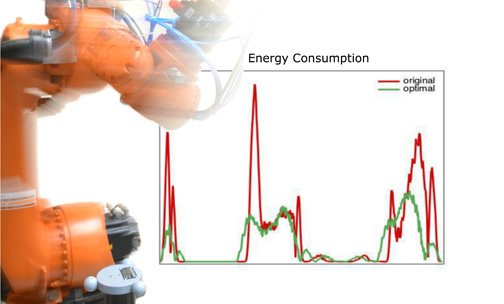

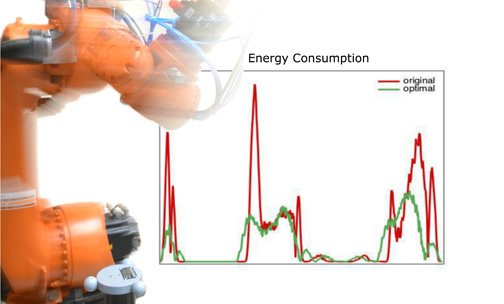

Machines Carbon Footprint calculator (on-going project)

The carbon footprint estimation of companies is a growing demand.

There is a need to evaluate the carbon emission of various fields, related to the company activity (materials, transformations, energy consumption,..).

A software tool is currently under developement, for computing the electrical energy consumption of robotic equipments, and then help optimizing machine usage.

The algorithm works by modeling the robot drives, computing applied torques on axes for a given path program, evaluate the overall energy consumption, and then estimate the carbon footprint.

Check out